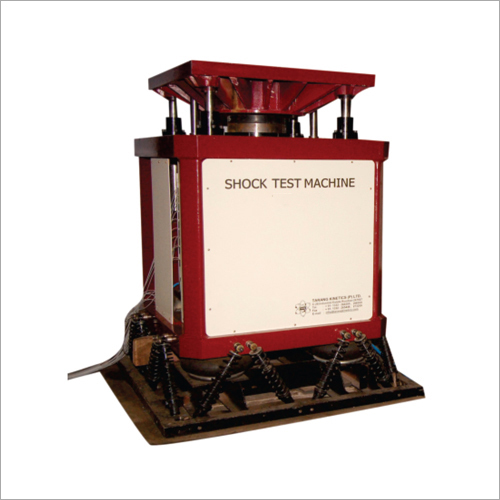

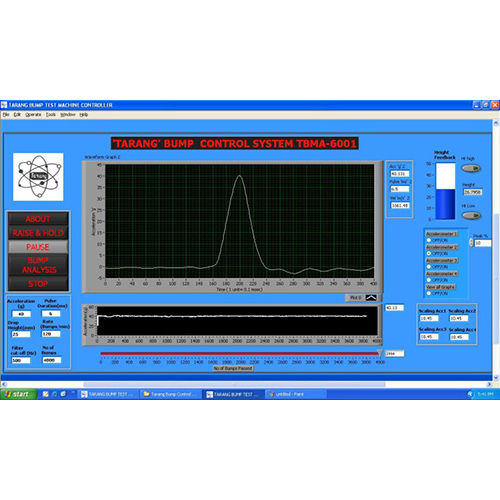

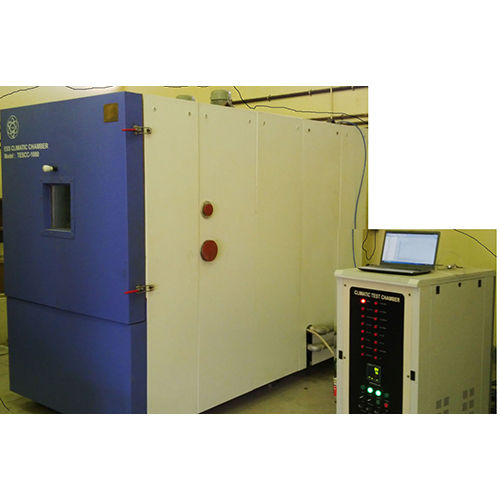

Most Popular Products

Showroom

|

TARANG KINETICS (P) LTD.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

|

TARANG KINETICS (P) LTD.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

For an immediate response, please call this

number 07313725917

Price: